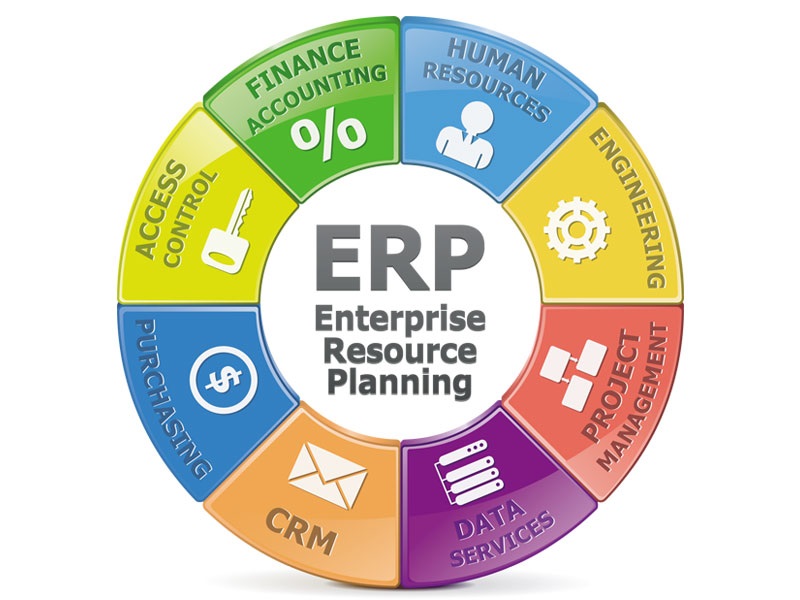

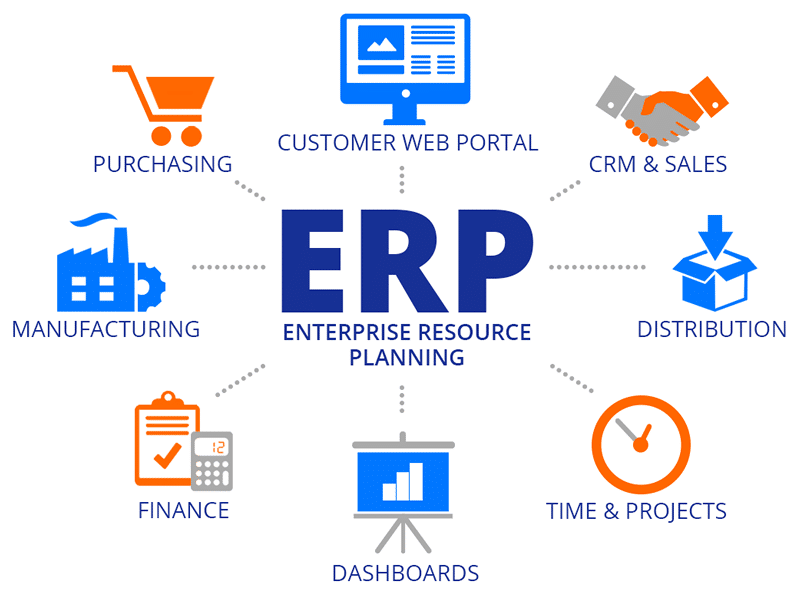

An ERP application is not just a commercial Business or Inventory management tool, technology-not just in handle, Error proof a process. An ERP module dealing with collection or recording Manufacturing data might also present an enhanced record process abilities.

An in process details are collected by performing Quality checks per Process Control plan stored within the ERP database. The data sheet arises from the procedure control plan, which clearly details how often of Quality checks, Sample size, Measurement Tools and finally who measures it. In situation your dimension or part characteristic measurement is missed, the wedding lot will not be accounted and therefore further processing inside the product cannot continue.

When the details are collected , it’s computed straight into CPK and Clubpenguin process capacity ratios, Which reveals when the dimension is well centered inside the specifications combined with the measurements posess zero broader spread ( meaning the choices of obtaining an unhealthy or from spec spend inside the batch is very low). Once the CPK lies at 1.67 the choices of by having an from spec part is below .003%.

The CPK and Clubpenguin needs to be computed for critical and key functional dimension within the part or component being manufactured, this practice enhances the advantages of the process.

Once the computed out put of CPK and Clubpenguin ratios while using ERP strategy is not acceptable, the system will instantly Flag the Batch as Suspect OR Hold, A hold tag will likely be instantly printed, with directions to quarantine the suspect lot in HOLD area.

The Hold are simple to remove while using Quality department after verification of containment actions. the Hold however needs to be removed or removed while using Qc Department while using the ERP system.

A Manufactured lot placed like a Suspect OR Under Hold by an ERP system, can’t be processed further meaning the In Process Data Sheet will not show approvals, Shipping Labels, Invoices, Packing slips Can’t Be Printed, there forefront all will not be shipped.

The ERP system coping with Concept Of Isolation has error proofed a producing process and Facilitated the process to complete within the Six Sigma quality level.